Department: Thermoforming

Thermoforming

As the increasing cleanliness requirements where the death of earlier bulk goods transported in card boxes thermoforming has become an inseparable part of the packaging industry.

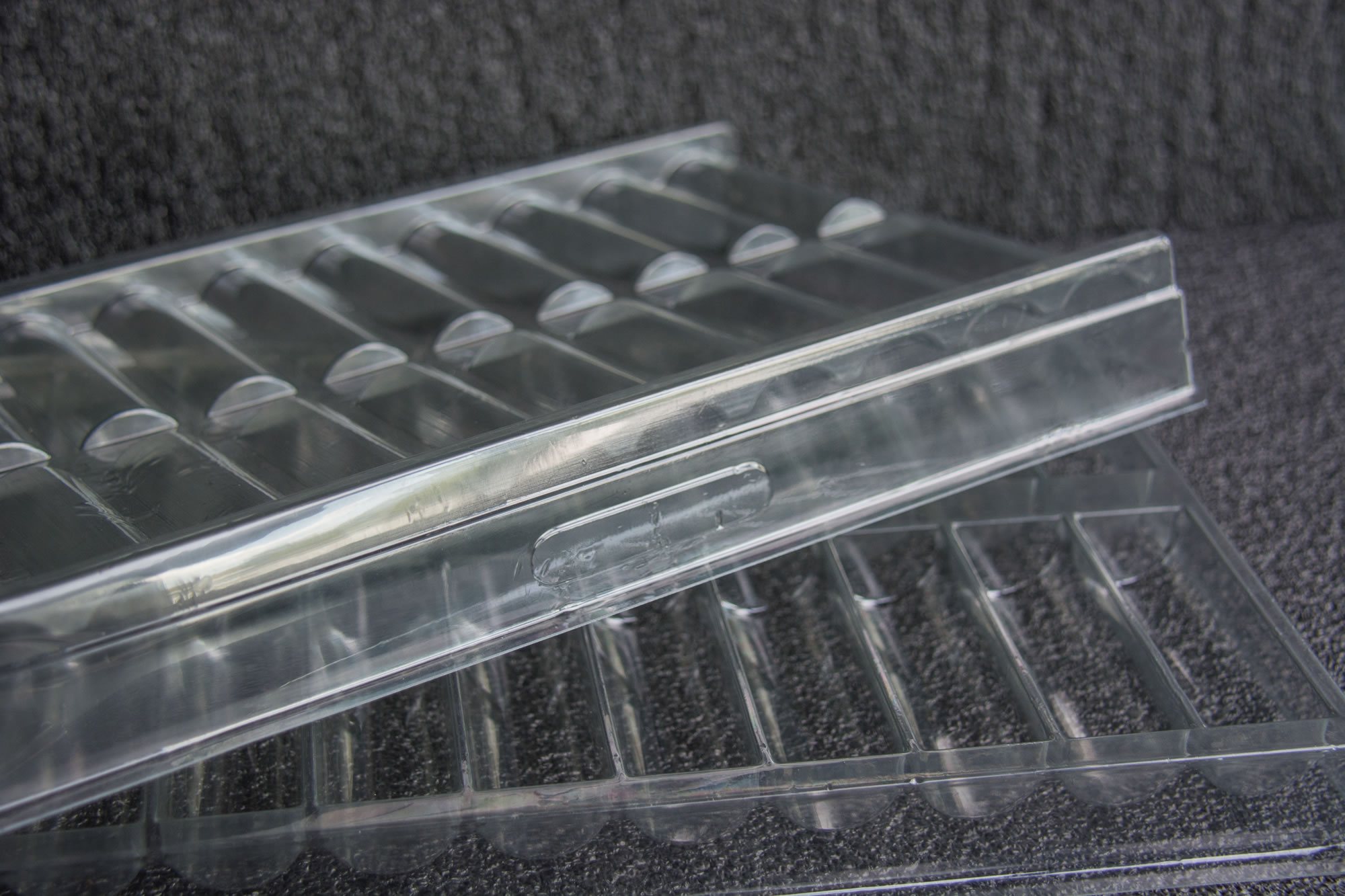

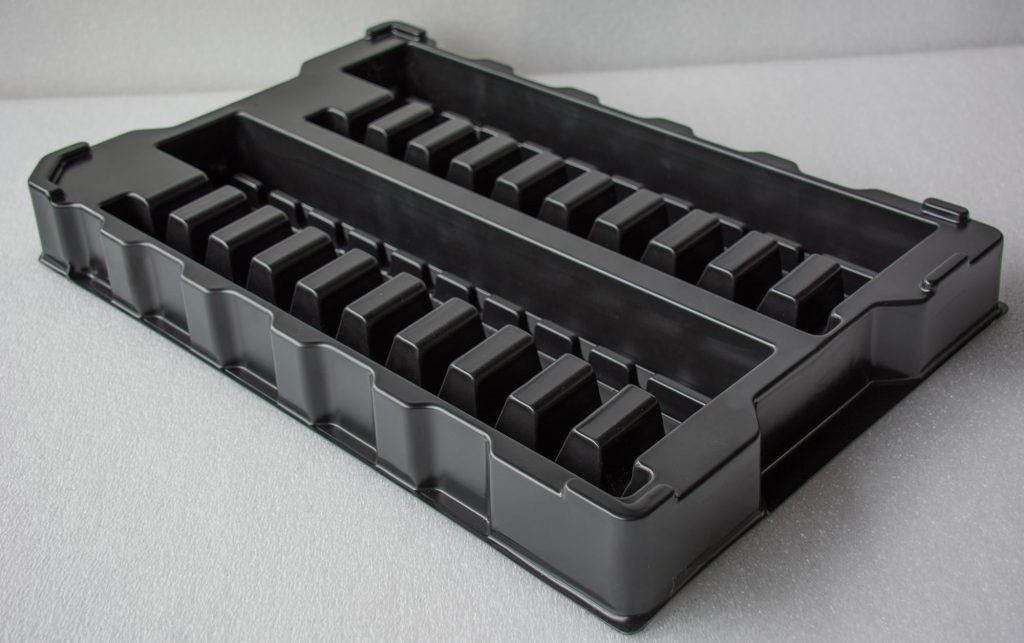

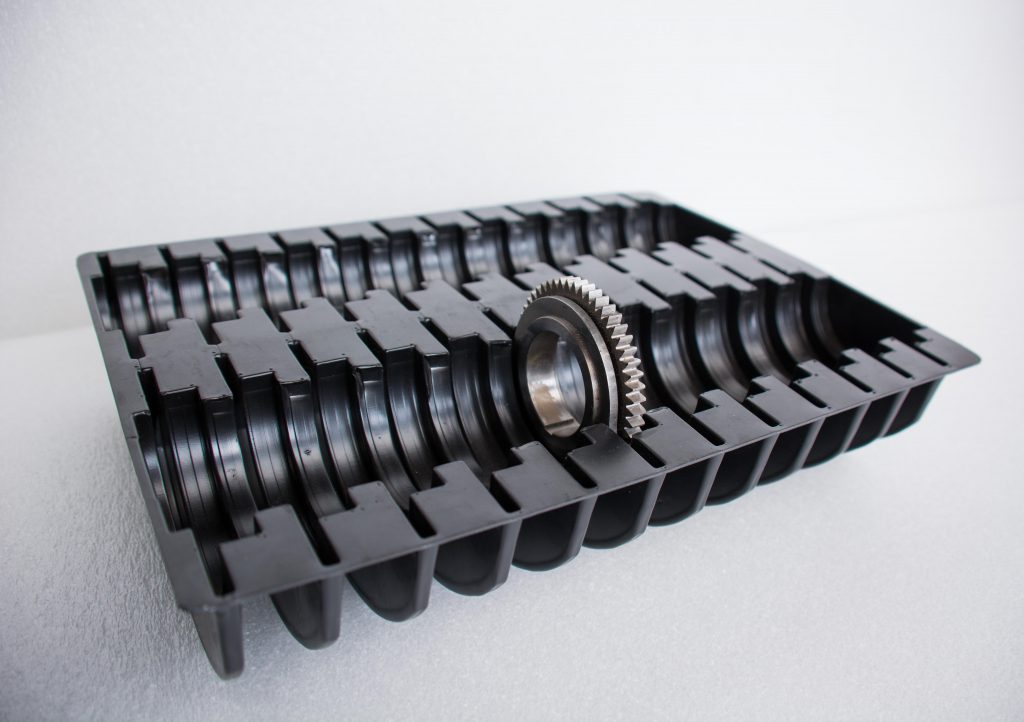

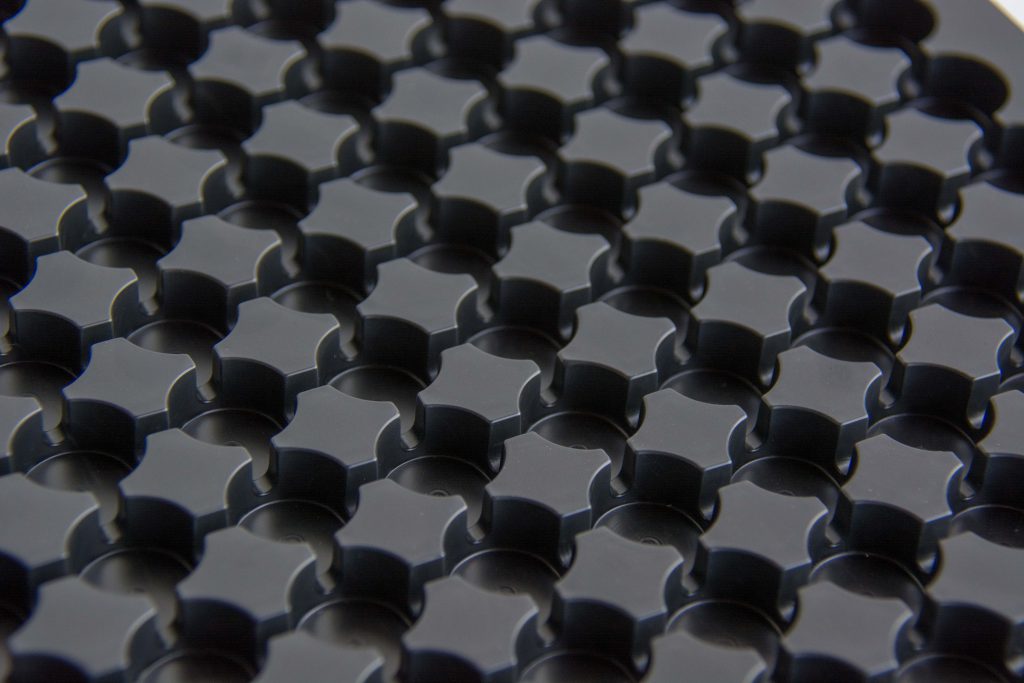

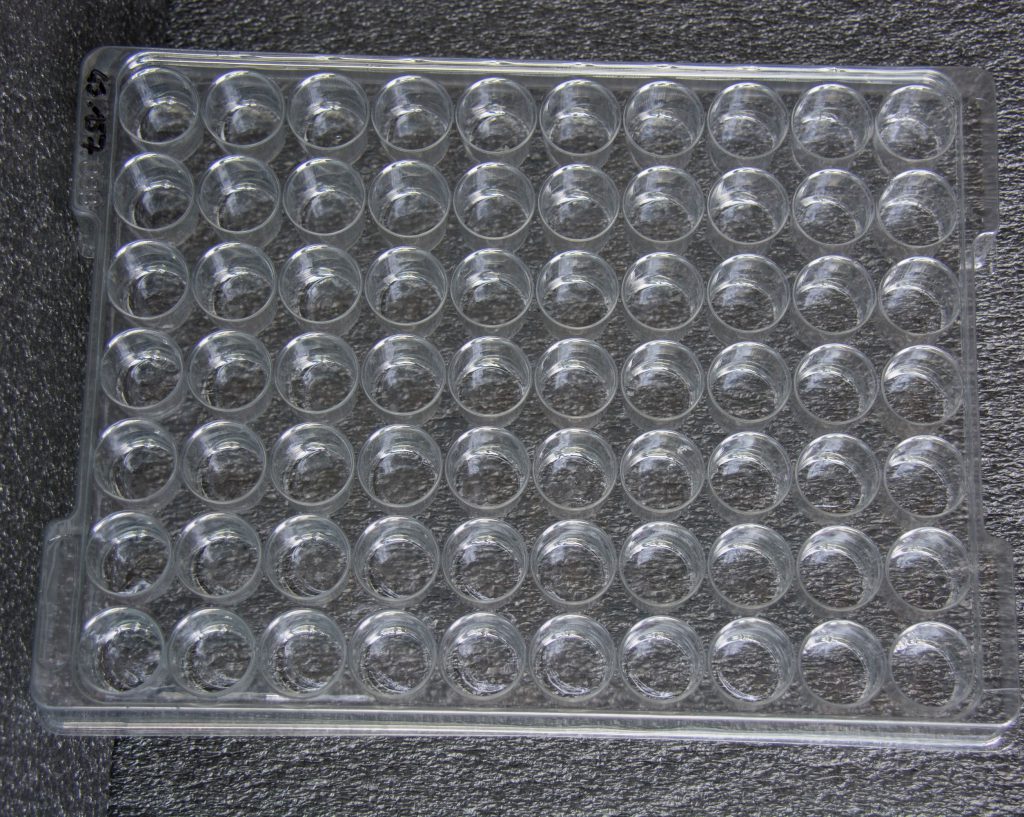

Vacuum formed trays are produced for perfect fit and space optimisation. They protect your products from damage during transport and enable more efficient counting due to pre-defined compartments. Thermoforming is used for both, manual and automated processes and simplify your logistics.

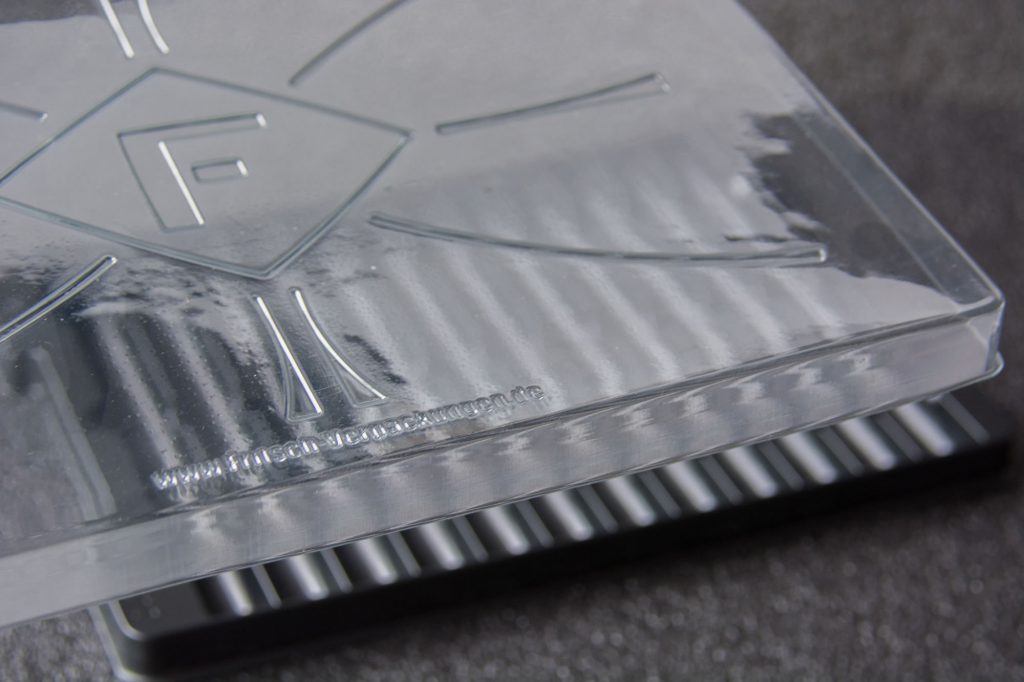

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold and gets trimmed for your requested dimension. The resulting tray is used e.g. in the automotive or medical industries as well as in many other sectors. The biggest advantage of thermoforming compared to injection moulding is its cost effectiveness.

We offer our customers both individualised and standardised packaging solutions. Our company’s structure allows us to produce also small quantities down to a minimum of 200 pieces. Over the years we have developed many tools and offer a high diversity our customers can choose from.

Our individualised solutions are customised for your process. We have more than 70 years of experience in the packaging industry and are specialised working on the edge of the possible. This enables us to offer our customers packaging solutions where other companies would already recommend injection moulding.

Depending on the requirements of our customers, we can manufacture all types of material (ABS, ABS-TPU, PS, PS/PE, PET, PVC and PE). We also offer recycled as well as antistatic and ESD materials. Thickness: 0.3 mm up to 12.0 mm